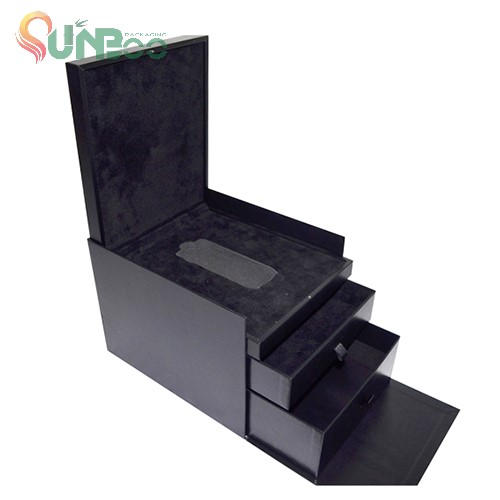

Metallic Paper 3 Layers Drawer Rigid Cardboard Box

Rigid box are made of the densest packaging material. These are mainly used for luxury and delicate products. Moreover, being premium quality packaging material, they add to the perceived quality of the product. Besides, customers don’t like throwing away such packaging that is protective and of high quality.

- SUNBOO

- CHINA

- 20 days around

- 150,000 pcs per month

- E- catalog.pdf

Details

To a large extent, the rigid box uses its exquisite shape and decoration to promote and beautify the product and improve the competitiveness of the product. Since the shape and structural design of rigid box are often determined by the shape and characteristics of the packaged goods, there are many styles and types, such as rectangles, squares, polygons, special-shaped cartons, cylinders, etc., but the manufacturing process is basically the same. .

| All information of Bags and Boxes | |

| Size of items: | Customized sizes(Length x Width x Height)cm |

| Materials: | Coated 1 side paper: 170gsm | 190gsm | 210gsm | 230gsm | 250gsm | 300gsm |

| Coated 2 sides paper: 128gsm | 157gsm | 180gsm | 220gsm | 250gsm | 300gsm | |

| Grey Cardoboard = 600gsm | 800gsm | 1000gsm | 1200gsm | 1400gsm | 1800gsm | |

| Color printing: | Offset | Flexo | Silk printing for PMS or CMYK |

| Surface Finishing: | Matt/Glossy lamination | Varnishing | Aqueous coating | Flocking | Gold/Silver hot stamping |

| | Debossed/Embossed | Texture | Spot UV | |

| Accessories: | Bags = Silk Ribbons | Grosgrain Ribbons | PP/Cotton handles | Plastic end | Eyelets |

| Boxes = Ribbons | PVC/PET tray | EVA | Sponge | Velvet | Cardboard | Flocking inserts | |

| Artwork Format: | AI | PDF | CDR |

| Custom Designs: | Bags = Hand-made paper bag | Twisted paper handles bag |

| Rigid boxes | Perfume Boxes | Foldable Boxes | Cosmetic Boxes | Wine Boxes | Chocolate | |

| Boxes | Watch Boxes | Round Boxes | Book Shape Boxes | |

| Sampleing Time: | 7 Days |

| Lead time: | 20-30 Days |

Rigid box production process

①Selection of paper

Consider the paper type, such as coated paper, fine art paper, pearlescent paper, etc.

Consider the thickness of the paper, and be careful not to make the paper too thick, otherwise the paper will wrinkle easily, and it should not be too thin, otherwise the embossing effect will not be reflected.

②Surface finishing

Glazing, reverse glazing, lamination (glossy film, matte film, tactile film, scratch-resistant film, etc.), embossing, hot stamping (gold, red gold, colored gold, silver, laser, etc.), partial UV

③ Gray board selection

Gray board is produced from a kind of recycled waste paper, mainly divided into single gray, double gray, full gray, high gloss, according to the customer's requirements for surface smoothness. Gray paper is an environmentally friendly packaging material. In special cases, there is no upper limit. Usually, gray boards of appropriate specifications are selected according to the specifications of the gift box.

④Die cutting

Rigid box have high technical requirements for die-cutting. The precision and accuracy of die-cutting directly affect the processing quality of subsequent processes and will directly determine the quality of products.

Die-cutting is a very important link in the manufacturing process, especially for gift packaging boxes, which have higher technical requirements for die-cutting. Precision and accuracy determine the quality of products, and slight errors directly affect the quality of subsequent processing. The terminology of die-cutting process name is;

4.1. Half-piercing (half-cutting): Cut out a line or a line of any shape with a depth not less than two-thirds of the thickness of the material on the cardboard or gray board with a die-cutting knife.

4.2. Die-cutting creasing: When die-cutting the gray board, make a positioning mark, usually add a half-piercing knife or a trace line, which is convenient for positioning when pasting.

⑤ Grooving

gray board slotting

Slotting is a key step in the production of Rigid box . Before the gray board is formed, the gray board must be removed in a V shape, so that after the gray board is bent, the outside is straight and the inside is square, with clear edges and corners, and the four corners match accurately. The term name for is;

5.1. Grooving: Use a slotting machine to open a V-shaped groove on a gray board with a thickness of 1--4MM, and generally keep a connection layer of about 0.25MM.

5.2. Groove angle: V-groove has an angle, generally 90 degrees, 120 degrees, or V-groove with different angles according to the product structure.

Note: After the gray board is bent, it must be straight on the outside and square on the inside, with sharp edges and corners, and the four corners match accurately.

⑥Paper

Assembly process

Mounting is a necessary process in the Rigid box process. According to different product requirements, the coated paper, art paper, flannelette, leather, etc. are glued or sprayed through the glue machine, and the gray board is tightly pasted together, so that the two are combined into one, so that the gray board The surface "renews the gray appearance", which not only beautifies the appearance of the box body, but also increases the added value of the packaging box.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)